Powder Coating Booths

Precision Engineered Powder Coating Booths for industrial use.

High-quality 3-stage filtration system puts our booths above the others.

Trust Powder-X Coating Systems to elevate your performance with precision and expertise.

Coating Booths for every business size

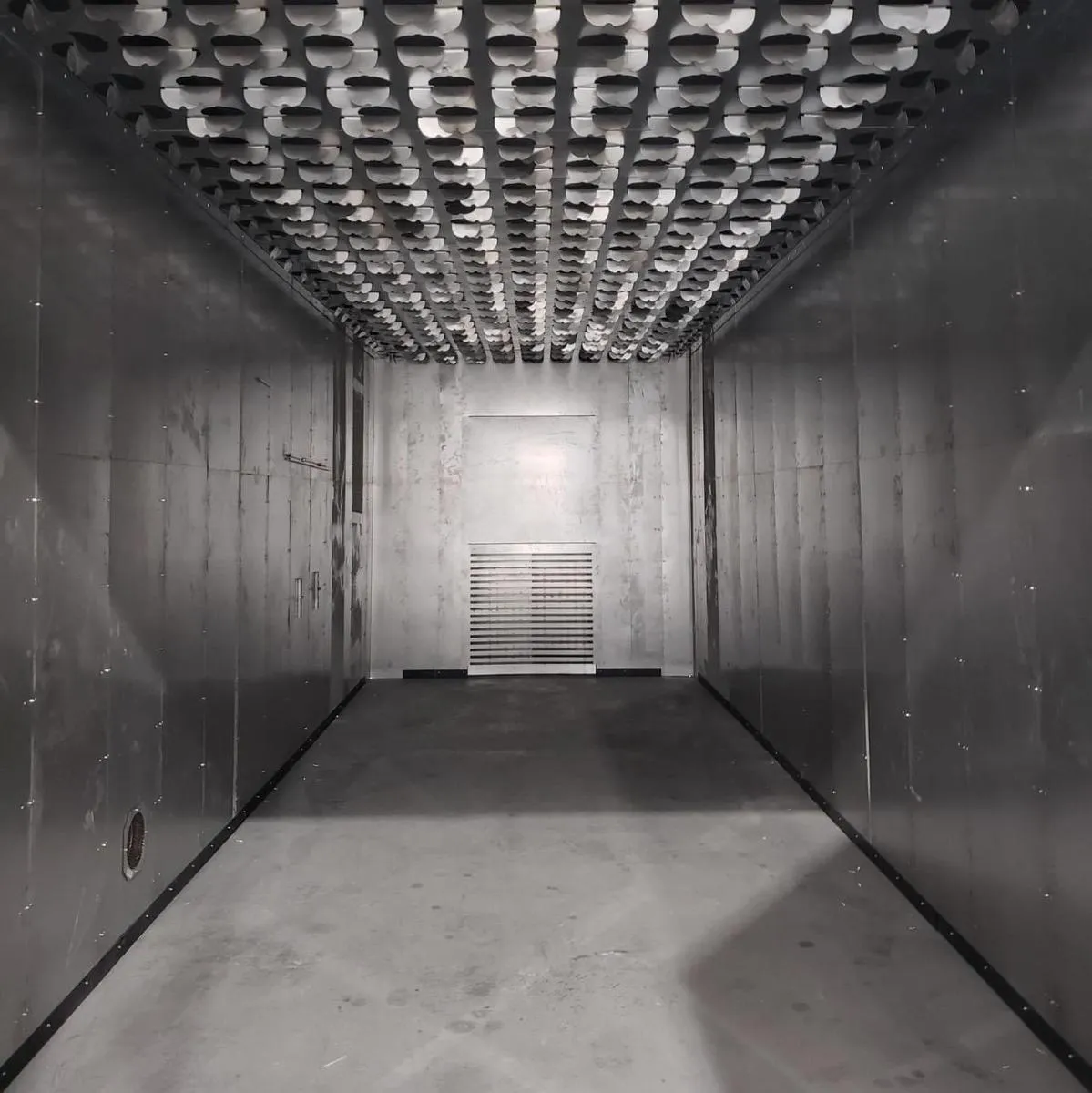

One of the most undervalued pieces of equipment needed in a powder coating operation is the powder coating containment booth.

Powder coating booths are not converted wet paint booths. The difference between wet paint booths and powder coating booths is the distribution of the air.

Powder-X is committed to maintaining our reputation as a leader of powder coating booth manufacturing by only offering a top-quality product at the best price and value available.

We are #1, because we sell the #1 best-quality booths since 2000!

Unlike liquid paint applications, powder coating contains no solvent or volatile organic compound (VOC ) emissions during the application, meaning that spray enclosure air can be filtered, then re-circulated back into the application room as opposed to being exhausted to the outside. This saves you thousands of dollars per year on environmental controls.

Proper design and manufacture of a powder coating booth is imperative for both code compliance as well as creating a quality finished product.

All Powder-X powder coating booths are designed to help you meet and exceed all code requirements. Constructed of 16-gauge galvanized metal, they are uniquely designed for increased durability and to reduce costs associated with installation and compliance.

Our three-stage spray-to-waste exhaust and filtration system is designed to exceed government specifications on high-efficiency commercial and industrial applications. Powder-X uses high-quality HEPA Final Filters, the same filtration used by most hospitals.

Cartridge module systems for reclaim are also available. Built in house, these are a fraction of the cost of most.

Now that you have decided to get a Powder-X booth the next step is to pair it with a matching powder coating oven of the same quality.

Customer Testimonials

Working with Powder-X has truly transformed our production line. Their equipment is not only state-of-the-art but also incredibly user-friendly. The training sessions were engaging and informative, giving our team the confidence to operate at peak efficiency. I can’t imagine our operations without the support and expertise of Powder-X.

Emily R

Production Supervisor, Precision Coatings LLC

Working with Powder-X has been a game changer for our business. Their equipment is not only reliable but also enhances our production capabilities. The training provided was exceptional, equipping our team with the knowledge to maximize efficiency. I highly recommend Powder-X to anyone looking to elevate their powder coating operations.

Micheal T

Operations Manager, Elite Finishes Inc.

Partnering with Powder-X has been a pivotal decision for our company. The quality of their equipment is unmatched, and the training sessions have empowered our team to uphold the highest standards of quality control. Our production efficiency has soared, and we are now able to meet our clients’ demands with confidence. I wholeheartedly endorse Powder-X for anyone serious about enhancing their powder coating processes.

Sarah L

Quality Control Manager, Advanced Finishing Solutions

Fire and Safety

Powder-X coating booths are classified as a Class B appliance for application of non-combustible materials and meet all related national codes related to NFPA 33 and national fire code. All electrical components including but not limited to motors, control panels (when applicable), light fixtures, and motor starters are all UL approved. In addition, all components also carry the much more stringent C-UL listing for Canadian Standards Association (CSA) approval.

Frequently Asked Questions

What size booth is needed for Powder Coating?

When selecting a booth for powder coating, size is a critical factor that depends largely on the items you intend to coat. Here’s how to decide on the right dimensions:

Object Size and Capacity: Assess Dimensions: The booth should comfortably fit the largest object you plan to coat, taking into account not just length, height, and width, but also ensuring there’s ample room around the item for air circulation.

Overestimate for Safety: It’s wise to opt for a booth slightly larger than your needs. This ensures that air can flow freely and heating is even, preventing spots or inadequate coating on larger pieces.

Consult Professionals: When in doubt, seek advice from powder coating experts. There are now dozens of coater's who have been fined by their local municipalities and many have had insurance and even leases cancelled due to having powder coating equipment that is not built to code. Build-it-yourself powder coating ovens have caused more than one person to lose their business and even their homes. When it comes to code and compliance – PROCEED WITH CARE!

How are powder coating booths delivered and installed?

When you order a powder coating booth, it typically arrives unassembled, giving you the flexibility to tailor the installation process to your specific needs. While many businesses successfully set up these systems themselves, a considerable number opt for professional installation to ensure everything operates seamlessly from day one.

What are the standard features and sizes of your powder coating booths?

Powder-X supplies hundreds of booths of all sizes. Whether you’re looking for a standard or custom solution, our powder coating booths offer a wide range of dimensions to suit any need.

How are the booths shipped?

The booths come in parts, making transport easier and more cost-effective. This modular approach allows for efficient delivery, regardless of your location.

Can I purchase an installation package?

If you prefer a quick and hassle-free setup, expert installation services are available. Installation teams, specialized in coating and curing systems, travel globally to assist.

Can I assemble the booth myself?

You have the option to assemble the booth using your own team or third-party services, although this might take a bit more time.

What are the differences between Liquid Paint Booths & Powder Coating Booths

When comparing liquid paint booths to powder coating booths, the biggest distinctions come down to how each finish behaves in the air and how it must be collected, filtered, and exhausted. Powder coating booths are engineered to handle a dry, charged particulate, while liquid booths must manage wet, solvent-based materials.

Your Partner in Excellence

Transform Your Coating Process

Join thousands of satisfied clients who have revolutionized their operations with Powder-X.

Your partner for high quality powder coating systems.