Safety Isn’t Optional. Neither Is the Right Setup.

If you’re asking, “Do I need a separate building for powder coating?” you’re already ahead of the curve. Powder coating is clean, efficient, and low-waste—but it’s still industrial work that involves:

- High voltage

- Open flame (in gas ovens)

- Fine particulate powders

- Overspray and recovery systems

- Intense heat from curing ovens

So, do you need a separate building or a fire-rated room to powder coat safely and legally?

Let’s break it down to see if your setup necessitates a different structure.

The Short Answer: It Depends on Your Setup and Local Code

There is no federal law that says you must have a separate building for powder coating.

BUT—most powder coating operations will require at least one of the following:

- A fire-rated space or enclosure

- Proper ventilation and dust collection

- Clearances between booths, ovens, and combustible materials

- Compliance with NFPA 33 (spray application safety)

- Approval from your local AHJ (Authority Having Jurisdiction)

When a Separate Building Is Required

You may need a separate structure if:

- You’re coating in a residential or multi-use space

- Your setup exceeds allowed heat or ventilation thresholds

- You’re unable to maintain required fire separation distances

- You want to simplify insurance, zoning, or fire marshal approval, which often requires assessing the need for a distinct building for powder coating.

Joey’s Rule of Thumb:

“If your current shop can’t meet code with ventilation, clearances, and safety systems—you don’t need a new building. You need a better plan.”

What Fire Marshals and Inspectors Look For:

Every county or city is different, but here’s what almost all AHJs will evaluate, including whether your setup demands separate facilities for powder coating.

Booth Location & Construction

- Must be UL-listed or made from non-combustible materials

- Must include integrated fire suppression or detection

Oven Placement

- Curing ovens must meet NFPA 86 and be installed away from flammable surfaces

- Gas-fired units need proper gas line clearance, ventilation, and access

Powder Handling Area

- Storage of powder in excess of 5 lbs must follow OSHA 1910.107 guidelines

- Fine powders + static = explosion risk without proper grounding and airflow

Electrical and Static Grounding

- Every Powder-X system includes grounding support and training to avoid risk

- Powder booths must be bonded and grounded according to code

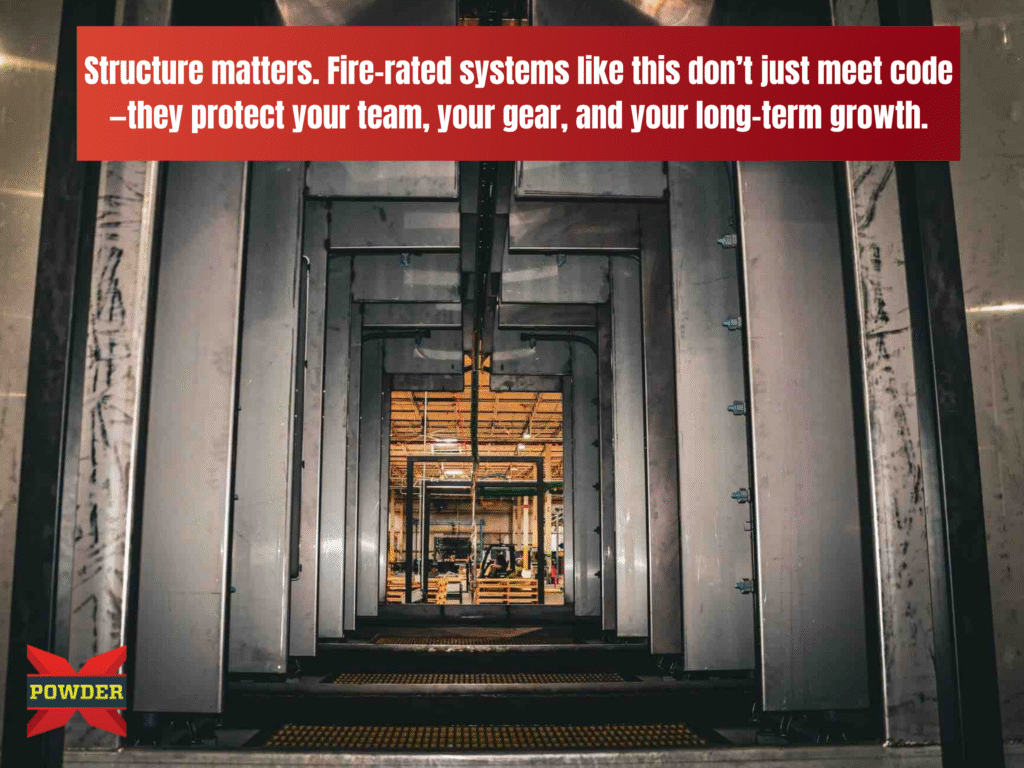

What About Fire-Rated Rooms?

You don’t always need a fire-rated room—but it helps.

Fire-rated spaces help you:

- Comply with commercial lease requirements

- Reduce insurance premiums

- Get automatic approval from city officials

- Protect your equipment investment

Bonus: Some fire-rated panels can be modular, so your “room” can grow as your shop scales, potentially negating the need for a separate building for powder coating.

How Powder-X Helps You Set It Up Right

We’ve helped 20,000+ coaters launch legally, safely, and without breaking the bank.

Here’s what we provide to help you stay code-compliant:

– System blueprints and shop layout planning

– Ventilation specs for your booth + oven

– Grounding & electrical load requirements

– Support to pass local inspections

– Guidance on zoning, permits, and insurance conversations

Final Word from Joey

“You don’t need to overbuild. You need to outplan. The best way to keep costs low and inspectors happy is to build it right from the start.”

Need a Site Planning Call?

Powder-X offers free layout consultations to help you design a setup that meets code and fits your space—whether that’s a garage, shop, or stand-alone building.

Schedule a call → 888-326-4840

https://powderx.com/service-visit/

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.107