\Is Your Pretreatment Process Holding You Back?

Every powder coater knows that the road to a flawless, durable finish starts long before the powder touches the metal. Proper pretreatment isn’t just a step—it’s the foundation of adhesion, corrosion resistance, and coating longevity.

Yet, many still rely on outdated pressure washers and chemical immersion tanks that consume excessive water, generate hazardous waste, and complicate regulatory compliance. The result? Higher costs, inefficiencies, and environmental headaches.

The Smarter Solution: Steam Pretreatment for Powder Coating with the Ultimate-X Steam Unit

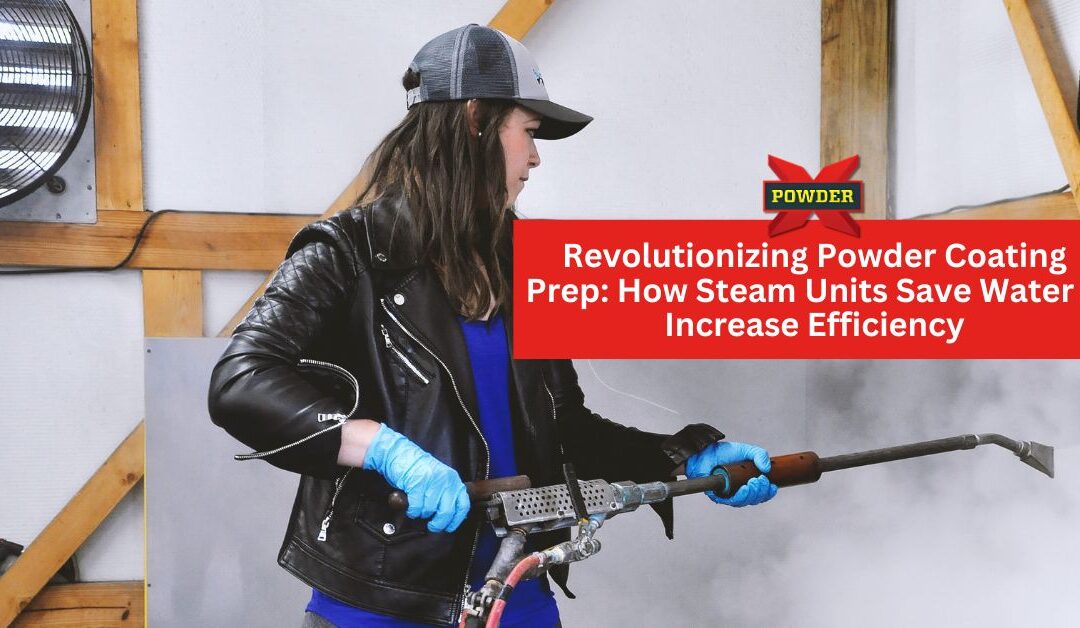

The game has changed. Forward-thinking powder coaters are upgrading to steam pretreatment for powder coating—a breakthrough technology that enhances cleaning, reduces water waste, and eliminates excess runoff. At the forefront of this revolution is the Ultimate-X Steam Unit, a system engineered to deliver deep-cleaning power with unmatched efficiency.

🔥 How the Ultimate-X Steam Unit Works

Unlike traditional pressure washers that blast gallons of water onto surfaces, the Ultimate-X Steam Unit takes a targeted approach:

Internal Heating: Water is heated to generate high-pressure steam.

Chemical Misting Technology: Chemicals are misted into the steam at the end of the wand for precise application.

Deep Penetration: Steam enters the metal’s microscopic pores, removing contaminants, oils, and oxidation.

The result? Superior cleanliness, stronger powder adhesion, and a fraction of the water consumption with steam pretreatment for powder coating.

🌍 Does It Require a Continuous Water Flow?

Yes—but far less than conventional methods.

Minimal Water Usage – Unlike pressure washers that require several gallons per minute, steam pretreatment for powder coating only uses the water needed to generate steam.

No Excess Runoff – Steam evaporates quickly, eliminating standing water and flash rusting.

Eco-Friendly & Cost-Effective – Less water usage translates to lower disposal costs and easier environmental compliance.

“Powder-X customers who switch to steam pretreatment for powder coating report dramatic improvements in efficiency and cost savings. If you’re still dealing with wastewater headaches, it’s time to rethink your process.” – Joey Golliver, Powder Coating Expert

🚀 Why More Powder Coaters Are Switching to Steam

Unmatched Cleaning Power – Steam pretreatment for powder coating penetrates deep into metal surfaces, outperforming traditional degreasers.

Faster Dry Time – Since steam doesn’t saturate parts, drying times are significantly reduced—meaning faster turnaround.

Stronger Powder Adhesion – The chemical misting process ensures even, thorough coverage for superior adhesion.

Lower Operating Costs – Less water, fewer chemicals, and reduced waste mean higher profit margins.

Regulatory Compliance Made Easy – If you’re struggling with wastewater disposal, steam pretreatment for powder coating eliminates that challenge entirely.

🔥 Is It Time to Upgrade Your Pretreatment Process?

If you’re still using gallons of water, dealing with inconsistent cleaning results, or navigating environmental compliance challenges, it’s time for a change.

The Ultimate-X Steam Unit is more than just an upgrade—it’s a game-changer for efficiency, quality, and sustainability.

📢 What’s your biggest challenge with pretreatment? Drop a comment below and let’s talk!

👉 Learn more about how the right steam pretreatment for powder coating system can boost your efficiency and quality. Contact Powder-X today!